|

MANUFACTURED BY US USING SUPERIOR RAW MATERIALS, CONFORMING TO INTERNATIONAL STANDARDS AND INDUSTRY REQUIREMENTS. ASTDM 3950. |

Today, SUREStrap (POLYESTER STRAP) is recognized as a new environment protective strap material to substitute Steel Strap & PP Strap, as it has the absolute advantages than other products, such as Better Pull Resistance, Superior Elasticity, Low Creep (Extension), Better Temperature Resistance, Excellent Rust Resistance, Alternative Colors, Easy Operation, Extreme Safety and Economy etc. PET straps are widely used in varied branches of industry, such as Can industry, Steel industry, architecture materials binding, chemical, fiber, industrial paper plants, glass industry, agriculture, tobacco, electronics, and so forth. |

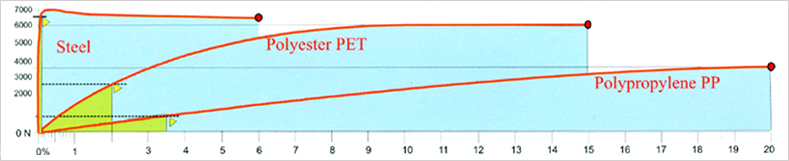

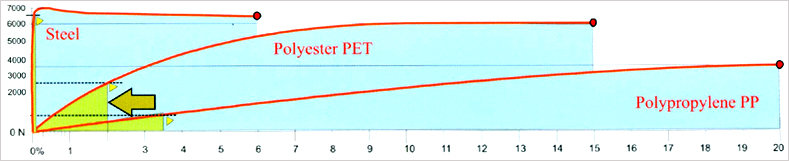

| The important factors for characterizing a strap for any application are : Strength, Working Range, Retained Tension, Elongation and Recovery. |

SUREStrap are characterized with High Tensile Strength, High Retained Strength and Retention. Other plastic straps split and lack in heavy duty load bearing. SUREStrap with its rust free, light weight engineering profile, is the next generation solution for safe fastening. In fact, it gives economical cost to performance vs. traditional fastening solutions including metal & typical plastic straps. |

| SUREStrap is 100% recyclable with ease and hence environment friendly and poses no threat. |

| |

| COMPARISON OF PROPERTIES : |

Material |

Break Strength |

Working Range |

Elongation Recovery |

Retained Tension |

Heat Resistance |

Humidity Resistance |

PP |

Moderate |

Lowest |

Marginal |

Fair |

Fair |

High |

Steel |

Highest |

Highest |

Negligible |

Highest |

Excellent |

Poor |

SUREStrap |

Good |

Good |

Good |

Good |

Good |

Excellent |

|

| SPECIFICATIONS OF SURESTRAP : |

|

Tensile Strength : |

| |

|

|

|

Recovery Capacity : |

| |

|

| |

| APPLICATIONS OF SURESTRAP : |

|

FIXED LENGTH SUREStraps FOR COTTON BALES ALSO AVAILABLE |

| SEALING PROCESSES : |

|

MECHANICAL SEALS : PET has hard, slippery surface hence it requires the use of serrated faced seals to prevent slippage. |

|

HEAT SEALING : A heat seal joint is created by a thermoelectric heater blade that melts and fuses two tensioned straps together under pressure. |

| |

FRICTION SEALING : A friction weld joint is formed by rapid vibration of two straps under tension creating enough frictional heat to fuse the straps together. |

| JUSTIFICATION FOR SWITCHING FROM STEEL TO SUREStrap |

| Today PET is recognized as environment protective strap material to substitute steel and PP. The advantages of SUREStrap vs. steel are outlined : |

|

Density of steel is 7.85, which is almost six times that of SUREStrap, i.e. higher mileage in SUREStrap. (Saves freight costs, ease in handling, less machine downtime as reduces frequent coil changes.)

|

|

SUREStrap has high elongation recovery, which is not there in steel

(Return to tight fit after elongation. Ideal for cotton/fibre as it can be sealed little loose initially) |

|

SUREStrap has excellent Tension Maintenance.

(It maintains tensile strength for a long stretch of time with minimized strap slacking, while ensuring excellent shock resistance ideal for long-distance, long-period transportation.) |

|

SUREStrap have good impact resistance.

(Takes 2.5 times energy vs. steel to break, when dropped and has better resistance to shock load.)

|

|

SUREStrap has superior weather resistance; Rust free and chemically inert.

(PET is preferred to steel straps in export packaging. It can be stored for longer time even in adverse temperature and moist conditions It does not stain the package, product or place of storage.)

|

|

SUREStrap is very safe at the destination while opening.

(Reduces accidents as it does not have sharp edges and does not ‘lash’ out when cut) |

|

SUREStrapping is fully recyclable to various products and easy disposal hence environment friendly. |

|

Aesthetics – Available in appealing colors and gloss. It does not leave mark on the pack. |

|

Economical and cost effective. |

|

| In current scenario, everyone is forced to look at alternatives to steel strapping and SUREStrap provides the ideal solution. SUREStrap is safer, cost effective, easier to use and environment friendly. Truly, SUREStrap fulfills the packaging needs of the new generation. |

| |

Manufacturer of

polyester straps, pp strap, pet straps,

surestrap |